Find Help

More Items From Ergsy search

-

UK Businesses Struggle with Supply Chain Delays Impacting Profits

Relevance: 100%

-

Health Officials Warn Against 'DIY' Health Remedies Amid Supply Chain Issues

Relevance: 35%

-

Will the Trump Tariffs affect my business?

Relevance: 32%

-

What should businesses do if they discover a product defect?

Relevance: 23%

-

Will my energy supply be interrupted if I switch suppliers?

Relevance: 23%

-

Is it possible to delay menopause naturally?

Relevance: 21%

-

What steps can a company take if shareholder disputes begin to impact business operations?

Relevance: 20%

-

Why might a court date be delayed?

Relevance: 20%

-

Can businesses be exempt from hosepipe bans?

Relevance: 20%

-

Impact of Cost of Living on UK Communities

Relevance: 19%

-

What should business owners expect from income tax changes in 2026?

Relevance: 19%

-

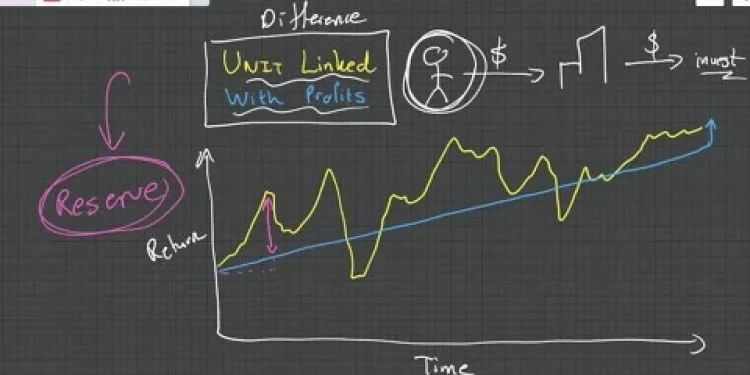

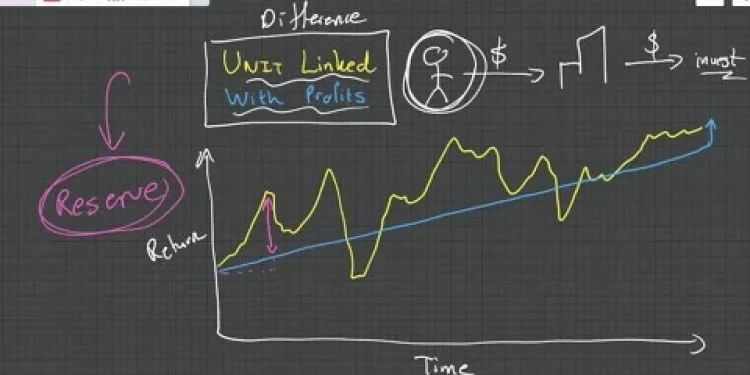

Life Insurance Difference between Unit Linked and With Profit Policies

Relevance: 19%

-

Government Faces Backlash Over Welfare System Access Delays

Relevance: 18%

-

What is the Small Business Administration (SBA)?

Relevance: 18%

-

How will the cuts impact landlords?

Relevance: 17%

-

Impact of Housing Shortage on Local Communities

Relevance: 17%

-

Can businesses claim the EV grant?

Relevance: 17%

-

Are there grants for businesses to install charging points?

Relevance: 17%

-

Does holiday insurance cover travel delays or missed connections?

Relevance: 17%

-

How do I apply for a small business loan through a government program?

Relevance: 16%

-

Are there government grants available for starting a small business?

Relevance: 16%

-

Can businesses be charged Stamp Duty?

Relevance: 16%

-

What is the eligibility criteria for government small business grants?

Relevance: 16%

-

Can businesses get grants for electric vehicles?

Relevance: 15%

-

Does the sugar tax apply to small businesses?

Relevance: 15%

-

How does the involvement of expert witnesses impact the timeline of a case?

Relevance: 15%

-

Can businesses apply for the Plug-in Car Grant?

Relevance: 15%

-

What types of government support are available for small businesses?

Relevance: 15%

-

Is the HMRC Employer Bulletin relevant for small businesses?

Relevance: 15%

-

Will the increase in the National Living Wage affect inflation?

Relevance: 15%

-

How does global energy demand affect UK energy prices?

Relevance: 15%

-

Impact of UK Housing Crisis on Local Communities

Relevance: 15%

-

Exercise Routines for Busy Parents

Relevance: 15%

-

Will Brexit affect my access to NHS dental treatments?

Relevance: 15%

-

How can I get government support for my small business?

Relevance: 15%

-

Can I get tax benefits for my small business from the government?

Relevance: 15%

-

Does the penalty point system apply to all businesses?

Relevance: 14%

-

Where can I find information on government support programs for small businesses?

Relevance: 14%

-

Will changing my surgery date impact my waiting time?

Relevance: 14%

-

Have energy prices in the UK historically fluctuated?

Relevance: 13%

Introduction

The recent disruptions in global supply chains have severely impacted businesses across the United Kingdom. These delays have resulted in significant challenges for companies trying to maintain their inventory levels, meet customer demands, and uphold profit margins. The ripple effects of these disruptions are being felt across various sectors, highlighting the fragility and interconnectedness of modern supply chains.

Causes of Supply Chain Delays

Several factors have contributed to the current situation. Firstly, the COVID-19 pandemic caused unprecedented disruptions in manufacturing and transportation logistics globally. Factories experienced temporary shutdowns, leading to reduced output and a backlog of orders. Additionally, shipping ports around the world have faced significant congestion, particularly notable at key transit points. This congestion has been exacerbated by a shortage of shipping containers and workforce limitations due to health protocols and travel restrictions.

Industry-Specific Impacts

The effects of these supply chain delays have varied across different sectors in the UK. Retailers, for example, have struggled to stock products on time, directly affecting their sales and customer satisfaction. The automotive industry has been particularly hard hit, facing shortages in crucial components like semiconductors, which are essential for vehicle manufacturing. Food and beverage sectors are also suffering delays, leading to concerns over spoilage and waste.

Implications on Profits

These supply chain issues have significant implications for UK businesses' profitability. Delays and shortages often lead to increased costs, whether due to expedited shipping charges, additional storage fees, or higher prices for scarce materials. Businesses are then faced with the difficult choice of absorbing these costs or passing them onto consumers, which can impact demand. For many small and medium enterprises, these pressures could threaten their sustainability if they lack the financial resilience to weather the storm.

Business Adaptation Strategies

In response to the ongoing challenges, many UK businesses are reevaluating their supply chain strategies. There is an increased focus on diversifying suppliers to reduce dependence on single-source or overseas suppliers. Some companies are investing in technology to better predict and manage supply chain disruptions, such as using data analytics and artificial intelligence. Others are considering nearshoring options or increasing local sourcing to mitigate risks associated with global supply chains.

Long-term Outlook

While some solutions are beginning to emerge, the long-term outlook for supply chain stability remains uncertain. The pandemic has accelerated the need for businesses to innovate and adapt quickly to changing circumstances. Policymakers and industry leaders are being urged to collaborate on developing more resilient supply chain strategies to safeguard against future disruptions. As the situation evolves, UK businesses are likely to continue facing challenges and adapting strategies to maintain competitiveness and profitability.

Introduction

Recently, getting things from one place to another has become very hard. This is because of problems in the way goods are moved around the world. Many companies in the UK are having trouble keeping enough products in stock. They are finding it hard to sell enough and make money because of these delays. Lots of businesses are feeling the effects. This shows how delicate and connected everything is in the modern world.

Why Are There Delays?

There are several reasons for the delays. First, the COVID-19 pandemic caused big problems around the world. Factories had to close for a while, so they made fewer things. They also had a lot of old orders to fill. Shipping ports, where goods are loaded and unloaded, are very crowded. This is worse because there are not enough shipping containers and there are fewer workers due to health rules.

How Different Industries Are Affected

Different industries in the UK are affected in different ways. Shops are finding it hard to get products on time. This means their customers are not happy, and their sales go down. Car makers are having a tough time because they cannot get important parts like semiconductors. Food and drink companies are also facing delays, which can lead to food going bad and being wasted.

Effects on Business Profits

These problems can hurt how much money UK businesses make. Being late and not having enough products can cost companies more money. This might be because they have to pay extra for fast shipping or storage. They might have to pay more for hard-to-get materials. Companies must decide if they will pay these costs themselves or ask customers to pay more. For many small businesses, this is a big problem, especially if they cannot afford it.

How Businesses Are Coping

To deal with these issues, many UK businesses are changing how they do things. They are trying to buy materials from different suppliers, not just one or ones that are far away. Some are using new technology to predict and manage problems better. This includes data analytics and artificial intelligence. Others are looking to buy more from nearby places to avoid problems with global deliveries.

What the Future Holds

While some new ideas are being tried, the future of supply chains is still unclear. The pandemic made it necessary for businesses to change quickly. Policymakers and industry leaders need to work together to make sure supply chains are stronger in the future. As things keep changing, UK businesses will have to keep finding ways to stay competitive and make a profit.

Frequently Asked Questions

What are common causes of supply chain delays for UK businesses?

Common causes include global shipping disruptions, customs delays, labor shortages, and increased demand for certain goods.

How can supply chain delays impact a business's profits?

Delays can lead to stock shortages, lost sales, increased costs for expedited shipping, and reduced customer satisfaction.

What immediate steps can businesses take to mitigate supply chain delays?

Businesses can increase inventory levels, diversify suppliers, and use alternative logistics solutions to reduce the impact of delays.

How can businesses improve supply chain resilience?

Businesses can invest in technology for better visibility, establish strong relationships with multiple suppliers, and develop contingency plans.

What role does technology play in managing supply chain delays?

Technology can provide real-time tracking, improve communication, and help in forecasting demand to better manage delays.

How do global events affect supply chain reliability?

Events like pandemics, trade wars, and political instability can disrupt shipping routes, cause port congestions, and impact overall supply chain reliability.

Should businesses consider nearshoring to reduce supply chain risks?

Nearshoring can reduce transit times and reliance on distant transportation networks, potentially lowering the risk of delays.

How does Brexit affect supply chain processes in the UK?

Brexit has led to increased customs checks, new documentation requirements, and potential tariffs, contributing to delays and increased costs.

What is the importance of demand forecasting during supply chain disruptions?

Accurate demand forecasting helps in inventory planning and ensures that businesses can meet customer demand despite supply chain challenges.

Can building local supplier networks help alleviate supply chain delays?

Yes, local suppliers can offer shorter lead times and reduce reliance on long international supply routes, helping to mitigate delays.

How do labor shortages affect supply chains?

Labor shortages can slow down production, lead to bottlenecks in warehouses, and increase delays in the shipping processes.

What are the financial implications of increased supply chain costs?

Businesses may face reduced profit margins, increased product prices, and the need to tap into financial reserves to cover unexpected costs.

How can businesses communicate effectively with customers during supply chain delays?

Maintaining transparency, updating customers regularly about delays, and offering alternatives can help manage customer expectations.

Is there government support available for businesses facing supply chain issues?

The UK government has provided certain funds and relief measures for businesses affected by supply chain disruptions, although specifics can vary.

Can inventory management strategies help in dealing with supply chain delays?

Yes, strategies like safety stock, just-in-case inventory, and predictive analytics can help manage supply shortages and demand surges.

How do transportation challenges contribute to supply chain delays?

Transportation challenges such as port congestion, lack of shipping containers, and driver shortages can significantly delay product deliveries.

What are the advantages of diversifying suppliers?

Diversifying suppliers reduces dependency on a single source, spreads risk, and can provide alternative options during disruptions.

How can just-in-time manufacturing be affected by supply chain slowdowns?

Just-in-time manufacturing is highly sensitive to delays, as it relies on precise timing of supply deliveries, leading to potential shutdowns or production hold-ups.

What long-term strategies can improve supply chain efficiency?

Investing in supply chain technology, forming strategic partnerships, and regularly reviewing and adjusting supply chain strategies can enhance efficiency.

How do geopolitical tensions impact supply chain operations?

Geopolitical tensions can lead to trade restrictions, increased tariffs, and disruptions in global supply networks, affecting supply chain operations.

What makes delays in getting supplies to UK businesses?

Some common reasons are problems with ships bringing things from other countries, customs checks taking a long time, not enough workers, and more people wanting to buy certain things.

How do delays in getting supplies hurt a business's money?

When a business takes too long to get the things it needs, it can lose money. This is because:

- They might not have enough products to sell.

- Customers might not want to wait. They could go to other stores.

- The business might have to pay more money to fix these delays.

Here are some tools and tips to help:

- Use calendars and alerts to keep track of orders.

- Talk to suppliers often to know when things will arrive.

- Have backup suppliers in case of problems.

When things are late, shops can run out of stuff to sell. This means they might lose money because people can't buy what they want. It can also cost more money to send things quickly to catch up. This can make customers unhappy.

What can businesses do right away to fix supply problems?

Businesses can keep more products, use different suppliers, and find new ways to deliver to avoid delays.

How can businesses make their supply chain stronger?

Businesses need strong supply chains to keep working well. Here are ways to help:

- Use computers to see the supply chain clearly. They help find and fix problems quickly.

- Work closely with suppliers. Talk often to know what everyone needs.

- Have extra supplies ready. This helps if there are delays.

- Train workers on new skills. This helps them solve problems fast.

- Plan for emergencies. Have a backup plan if something goes wrong.

Using tools like computers and having a good plan helps keep supply chains strong. Businesses should talk often with everyone involved and be ready for any surprises.

Businesses can use technology to see what is happening better. They should also make good friends with different suppliers and have backup plans ready.

How can technology help with supply chain delays?

Technology can help us in many ways. It can show us where things are right now, help us talk to each other better, and guess how many things we will need in the future. This way, we can stop things from being late.

If you find reading hard, you can use tools like text-to-speech apps. These apps can read the text out loud for you. Trying to read a little every day will also help you get better.

How do big world events change the way goods are delivered?

Big events in the world can change how items are moved from place to place. This can make it easier or harder for things to arrive on time.

- Examples of big events are natural disasters, wars, or big changes in government rules.

- These events can make it take longer for ships, trucks, or planes to bring goods.

- People may have to find new ways to get items to the stores.

Some helpful tools or tips include:

- Use simple maps or diagrams to see where items travel from and to.

- Make a list of items you need early, so you can wait if there are delays.

Big events like when lots of people get sick, countries stop trading, or governments have problems can mess up how things are shipped. This can mean that ships get stuck and things don’t arrive on time.

Should businesses move work closer to make supply chains safer?

Businesses might think about bringing work and suppliers closer to where their main operations are. This can help make their supply chains safer and more reliable.

Here are some ideas to make this easier for everyone:

- Maps and Pictures: Use maps and pictures to show what nearshoring means.

- Simple Words: Explain new words slowly and with simple examples.

- Break it Down: Break the information into small, easy parts.

- Support Tools: Use apps or helpers that read text out loud or offer simple explanations.

Using these tips can help everyone understand and decide if moving work closer is a good idea.

Nearshoring means getting things from places closer to home. This makes delivering things quicker and helps avoid long trips. It also means there are fewer chances for things to get delayed.

How does Brexit change how goods move in the UK?

Brexit means the UK is no longer in the European Union (EU). This can change how goods are made and moved in and out of the UK.

Here is what can happen:

- There might be new rules for bringing goods into the UK and sending goods out.

- It might take longer for goods to arrive because of these new rules.

- Some things might cost more because of taxes or fees.

Helpful tips:

- Use pictures or symbols to help understand the process.

- Watch short videos that explain Brexit changes.

- Ask someone you trust if you have questions.

Brexit means there are now more border checks. This means more paperwork and maybe extra charges too. This can make things slow and cost more money.

Why is it important to predict what people want to buy when there are problems with getting products?

When businesses know what customers want, they can plan well and have enough products available. This helps them sell what people need, even if there are problems getting products from suppliers.

Can working with local suppliers help reduce delivery delays?

Can using nearby suppliers make deliveries faster?

- Deliveries mean bringing goods to where they are needed.

- Suppliers are people or companies that provide the goods we need.

- Local means close by or nearby.

Tips to help understand:

- Use drawings or diagrams to see how deliveries work.

- Ask someone to explain if you're unsure.

- Make a list of local suppliers you know.

Yes, local suppliers can get things to you faster. They don’t have to use long international routes, so there can be fewer delays.

Here are some tools that can help you understand better:

- Reading Aloud Tools: These read the text out loud for you.

- Picture Dictionaries: These show pictures next to the words to help explain them.

- Highlighting: This lets you mark important parts with colors to make them stand out.

How do not enough workers change supply chains?

When there are not enough workers, it can make it hard to move things from one place to another. This is called a supply chain problem.

Here are some things that can happen:

- Things take longer to get to the store or to people.

- There might not be enough things to buy.

- Things might cost more money.

To help understand these changes, you can:

- Use pictures or drawings to show how things move from place to place.

- Work with a friend or family member to talk about it.

- Use apps or websites that explain this in simple ways.

If there are not enough workers, making things takes longer. This can cause big slowdowns in places where goods are kept, like warehouses. It also makes it take more time for things to be delivered.

What happens to money when supply chain costs go up?

Businesses might make less money. They might need to raise their prices. Sometimes, they have to use their savings to pay for surprises.

How can businesses talk well with customers during delivery delays?

When deliveries are slow, it's important for businesses to talk clearly to their customers. Here are some tips:

- Tell customers about the delay as soon as possible.

- Explain why the delivery is late in simple words.

- Say when you expect the delivery to arrive.

- Be honest and polite when giving updates.

- Offer help if the customer has questions.

Businesses can use tools like emails or text messages to keep in touch. Keeping the message short helps everyone understand better.

It is important to tell customers what is happening. If things are running late, let them know. Give them other choices if you can. This helps customers understand and feel better.

Can businesses get help from the government with supply problems?

The UK government has given money and help to businesses. This is for businesses that have problems getting or sending goods because of supply chain issues. The details might be different for each business.

Can planning how we store and use items help with delivery delays?

We all need supplies, like food or toys. Sometimes those supplies take a long time to arrive. When this happens, it can be frustrating.

But, there are ways to help! Here are some tips:

- Plan Ahead: Try to order things before you run out. This way, if there is a delay, you still have what you need.

- Keep Track: Use a list or a chart to see what items you have and what you need to get soon.

- Find Alternatives: If one item is late, think about using something else for the time being.

These ideas can make waiting for supplies a little easier.

Yes, there are ways to help when there are not enough products or when too many people want to buy.

- Safety stock: This means having extra products ready, just in case they are needed.

- Just-in-case inventory: This is keeping a small amount of extra stock to be ready for surprises.

- Predictive analytics: This means using tools to guess what will happen and be ready for it.

These ways make sure there are enough things for everyone.

How do travel problems make delivery slow?

Sometimes, when moving things from place to place, problems can happen. These problems make it take longer for the things to get where they need to go. When roads are busy or there are bad weather conditions, trucks and ships can be slow. This makes delivering stuff late.

Helpfull tips:

- Use a dictionary to look up words you don't know.

- Ask someone to explain things if you're unsure.

- Draw a picture to understand how things move from one place to another.

Getting things delivered can be slow. This happens when there are too many ships waiting, not enough big boxes to move stuff, or not enough drivers. These things can cause big delays.

Why is it good to have different suppliers?

Using different suppliers means you don't rely on just one. This helps if something goes wrong with one supplier, and you have others to turn to.

How does just-in-time manufacturing get impacted when the supply chain is slow?

Just-in-time manufacturing is a way to make products where parts come just when needed. This helps save money and space. But if the supply chain is slow, parts can arrive late. When parts are late, factories can't make products on time.

Use pictures or diagrams to show how parts move from one place to another. This can help understand the supply chain better.

Just-in-time manufacturing is a way of making things where parts arrive at the exact time they are needed. If there are delays, it can cause big problems, like stopping work or slowing down production.

How can we make supply chains better for a long time?

Using smart tools for managing how things are made and sent can make things work better. Working together with other companies can also help. It's a good idea to look at how things are going and make changes when needed.

How do problems between countries affect supply chains?

Big problems between countries can cause trouble for businesses. This can make it hard to get things they need.

When countries argue, it can slow down or stop the movement of goods. This can make things more expensive and take longer.

To understand better, you can watch videos or use picture charts. Reading tools can also help you learn more.

Sometimes, countries might not get along well. This can make it harder for them to trade with each other. It might cost more money to buy things from other countries. This can make it difficult for businesses to get what they need.

Useful Links

This website offers general information and is not a substitute for professional advice.

Always seek guidance from qualified professionals.

If you have any medical concerns or need urgent help, contact a healthcare professional or emergency services immediately.

- Ergsy carfully checks the information in the videos we provide here.

- Videos shown by Youtube after a video has completed, have NOT been reviewed by ERGSY.

- To view, click the arrow in centre of video.

- Most of the videos you find here will have subtitles and/or closed captions available.

- You may need to turn these on, and choose your preferred language.

- Go to the video you'd like to watch.

- If closed captions (CC) are available, settings will be visible on the bottom right of the video player.

- To turn on Captions, click settings .

- To turn off Captions, click settings again.

More Items From Ergsy search

-

UK Businesses Struggle with Supply Chain Delays Impacting Profits

Relevance: 100%

-

Health Officials Warn Against 'DIY' Health Remedies Amid Supply Chain Issues

Relevance: 35%

-

Will the Trump Tariffs affect my business?

Relevance: 32%

-

What should businesses do if they discover a product defect?

Relevance: 23%

-

Will my energy supply be interrupted if I switch suppliers?

Relevance: 23%

-

Is it possible to delay menopause naturally?

Relevance: 21%

-

What steps can a company take if shareholder disputes begin to impact business operations?

Relevance: 20%

-

Why might a court date be delayed?

Relevance: 20%

-

Can businesses be exempt from hosepipe bans?

Relevance: 20%

-

Impact of Cost of Living on UK Communities

Relevance: 19%

-

What should business owners expect from income tax changes in 2026?

Relevance: 19%

-

Life Insurance Difference between Unit Linked and With Profit Policies

Relevance: 19%

-

Government Faces Backlash Over Welfare System Access Delays

Relevance: 18%

-

What is the Small Business Administration (SBA)?

Relevance: 18%

-

How will the cuts impact landlords?

Relevance: 17%

-

Impact of Housing Shortage on Local Communities

Relevance: 17%

-

Can businesses claim the EV grant?

Relevance: 17%

-

Are there grants for businesses to install charging points?

Relevance: 17%

-

Does holiday insurance cover travel delays or missed connections?

Relevance: 17%

-

How do I apply for a small business loan through a government program?

Relevance: 16%

-

Are there government grants available for starting a small business?

Relevance: 16%

-

Can businesses be charged Stamp Duty?

Relevance: 16%

-

What is the eligibility criteria for government small business grants?

Relevance: 16%

-

Can businesses get grants for electric vehicles?

Relevance: 15%

-

Does the sugar tax apply to small businesses?

Relevance: 15%

-

How does the involvement of expert witnesses impact the timeline of a case?

Relevance: 15%

-

Can businesses apply for the Plug-in Car Grant?

Relevance: 15%

-

What types of government support are available for small businesses?

Relevance: 15%

-

Is the HMRC Employer Bulletin relevant for small businesses?

Relevance: 15%

-

Will the increase in the National Living Wage affect inflation?

Relevance: 15%

-

How does global energy demand affect UK energy prices?

Relevance: 15%

-

Impact of UK Housing Crisis on Local Communities

Relevance: 15%

-

Exercise Routines for Busy Parents

Relevance: 15%

-

Will Brexit affect my access to NHS dental treatments?

Relevance: 15%

-

How can I get government support for my small business?

Relevance: 15%

-

Can I get tax benefits for my small business from the government?

Relevance: 15%

-

Does the penalty point system apply to all businesses?

Relevance: 14%

-

Where can I find information on government support programs for small businesses?

Relevance: 14%

-

Will changing my surgery date impact my waiting time?

Relevance: 14%

-

Have energy prices in the UK historically fluctuated?

Relevance: 13%